Success Stories

FeatureCAM Improved Programming Speed by 40%

Customer Challenge Chips MFG is part of the dental division at Steris Corporation. Our company specializes in manufacturing dental and medical components. We have been using Autodesk PartMaker for over 13 years and we are very satisfied with it, but over the years our parts portfolio changed. We started to produce bigger and more complex…

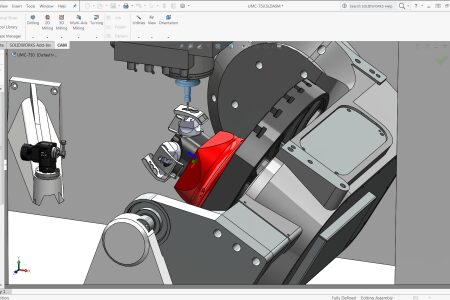

Customer Challenge Early experience with Pratt & Whitney on the joint strike fighter program gave me a real-world appreciation for sub-tenths precision and high-end manufacturing processes. While a design and engineering manager for a high-end architectural sign company, some community college machine shop training gave me a start in hands-on machining. This culminated in an…

Zero Defects by Using Moldflow

Customer Challenge For 60 years, OTTO Engineering has been designing and manufacturing a full line of control switches and for over 25 years, audio accessories for unique and demanding applications. Located in Carpentersville, Illinois, we are recognized worldwide for superior performance and innovative products. OTTO Engineering is a vertically integrated manufacturer with in-house injection molding,…

Custom Fusion 360 Post Delivered in Under 24 Hours

Customer Challenge Angel City Woodshop was born in early 2016, founded by Paul Moorhead. Paul was a self-taught furniture maker and operated alone for some time. Over the years we have expanded into a team and have built a reputation in Los Angeles as one of the premier high-end custom furniture shops in the city….

Customer Challenge Sinicon Plastics was founded by a man named Tony Sinico. A child of the Great Depression and first generation Italian-American. In 1989, our current owner, David Allen, purchased Sinicon from Tony and his son. When David bought the company there were seven employees and eight machines located in an old, 5,000 sq ft…