- All

- Blog

- Design

- Featured on Home Page

- Fusion

- Mold & Die

- PowerMill

- PowerShape

- Prototyping

By Chase Clayton |

Autodesk Versus: How PartMaker Ranks in Swiss Machining Software

In the realm of CNC machining, Swiss-style lathes stand out for their ability to produce precise, intricate parts ...

Read More By Chase Clayton |

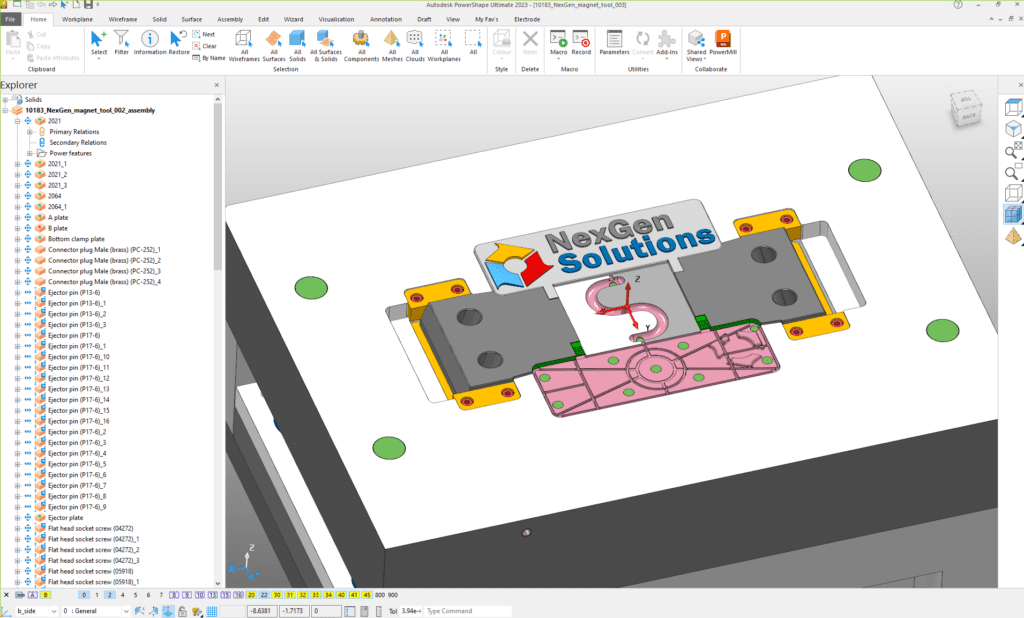

How Autodesk’s PowerShape & PowerMill Streamline Electrode Design

We all know how critical electrode design, manufacturing, and machining are in making sure your facility can remain ...

Read More By Chase Clayton |

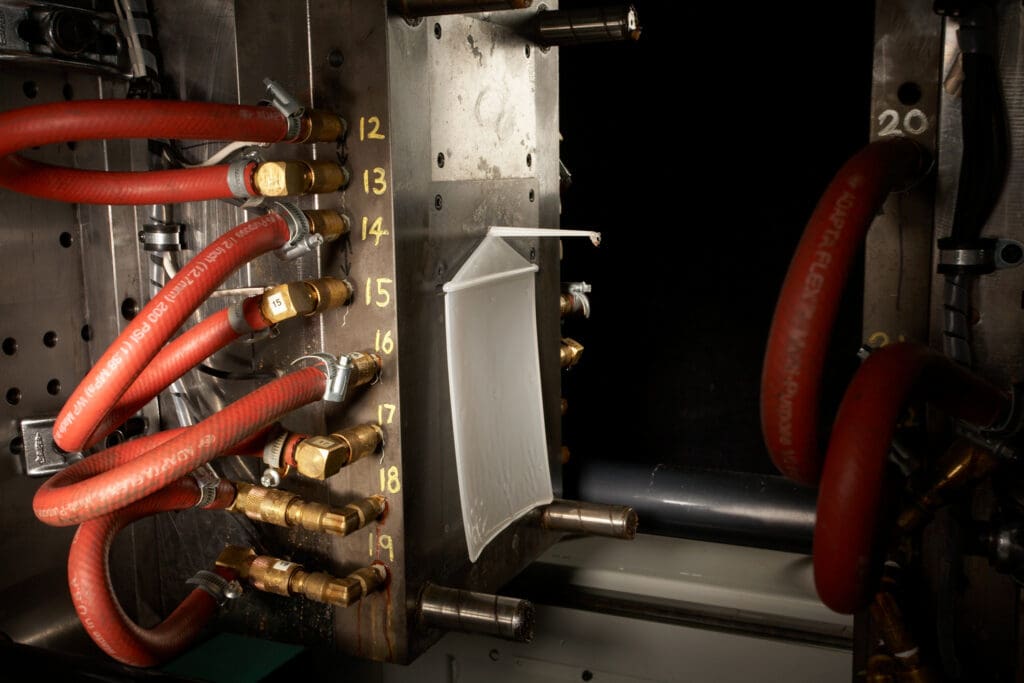

How PLM Technology is Casting the Future

With advances in technology around additive manufacturing (aka 3D printing or rapid prototyping), there's been a large increase ...

Read More By Chase Clayton |

Mastering Mold Making: Elevating Production with Fusion’s Advanced Toolpath Strategies

In the ever-evolving manufacturing environment, precision and efficiency are crucial. Mold making, a key industry of CNC machining, ...

Read More By Chase Clayton |

The Evolution of Prototyping: Embracing Digital Tools for Smarter Design

Prior to the introduction of CAD, prototyping was comprised of the following phases: Idea Hand Drawn Sketch Hand ...

Read More By Chase Clayton |

From Concept to Creation: A Comprehensive Guide to Prototyping with Autodesk Fusion

The Advancement of Prototyping The practice of prototyping has been a staple in any engineering and manufacturing practice ...

Read More